The power plant water treatment system is a core auxiliary system that ensures the safe and stable operation of power generation equipment and enhances energy efficiency. Its primary objective is to remove impurities from water, control water quality parameters, prevent boiler scaling, pipeline corrosion, and salt deposition on steam turbines, and achieve the recycling of water resources.

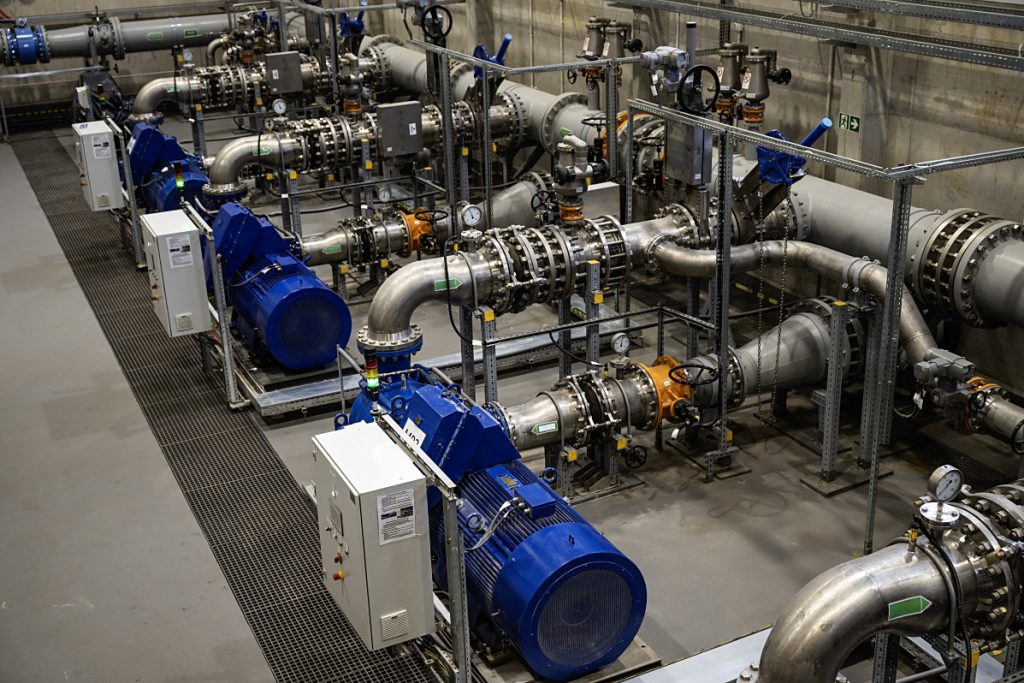

The system mainly comprises four key treatment stages. Firstly, raw water treatment focuses on raw water from rivers, lakes, etc. Through coagulation, sedimentation, and filtration, suspended solids, colloids, and some organic matter are removed. Disinfection (e.g., using sodium hypochlorite) is also employed to inhibit microorganisms, laying the foundation for subsequent advanced treatment. Secondly, boiler make – up water treatment is necessary as boilers have extremely high water quality requirements (low salt and low oxygen). Reverse osmosis and ion exchange (e.g., cation exchange beds, anion exchange beds, and mixed beds) are used for advanced desalination. Then, thermal or chemical deoxygenation (e.g., adding hydrazine) is carried out to eliminate dissolved oxygen and prevent corrosion of boiler metals. Thirdly, condensate water treatment involves the recovery of the condensed water from the steam turbine exhaust. Through mixed – bed ion exchange, corrosion products (e.g., iron and copper oxides) and trace dissolved salts are removed, increasing the water resource recovery rate and reducing the demand for make – up water. Fourthly, circulating water treatment targets the circulating water in the cooling system. Scale inhibitors and corrosion inhibitors are added to control scaling and corrosion, and biocides and algaecides are used to inhibit the growth of microorganisms (e.g., Legionella), ensuring the efficiency of cooling towers and heat exchangers.

The system needs to monitor parameters such as pH, conductivity, and dissolved oxygen in real – time through online instruments and dynamically adjust the dosage of chemicals and treatment processes. Its stable operation is directly related to the service life of the generating units (e.g., reducing the frequency of boiler maintenance), power generation efficiency (avoiding the decline of heat exchange efficiency), and environmental benefits (reducing wastewater discharge), serving as an important guarantee for the safe and economic operation of the power plant.